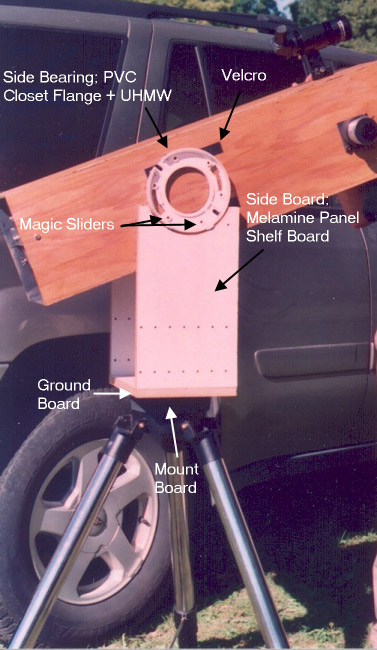

While contemplating on building a telescope of my own design, I decided to use existing optics from other telescopes and stuff from the ATM vault of stuff I forgot I had. I wanted to be able to use various finder scopes, eyepieces and secondary mirrors on this particular telescope. This also means you need some type of adjustable (re-programmable) side bearing to compensate for the different changes in weight to balance the telescope and make it more multifunctional.

I have often thought about using Velcro to hold the side bearings (altitude) to the telescope tube and eliminate the cradle and/or sliding weight to balance the tube. By using two strips of Velcro you could reposition the side bearing on the tube and compensate for the weight (balance point) of the telescope. The telescope tube pictured is a square wood tube that is 36’ long and holds an 8” f4.5 mirror.

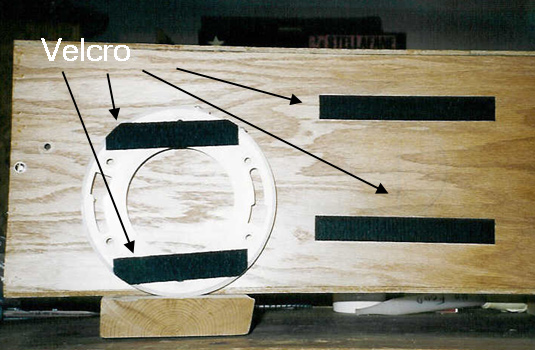

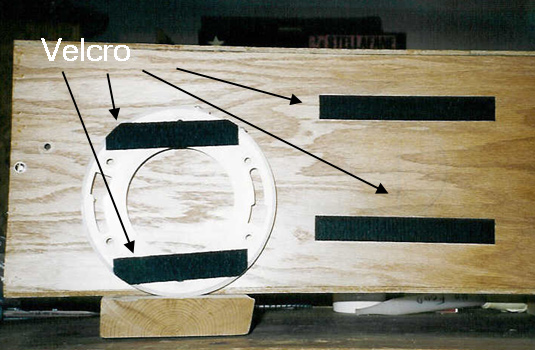

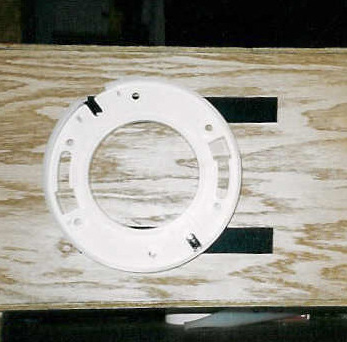

As you can see from the above picture, two self sticking Velcro strips each 7 inches long are attached to both sides of the square telescope tube. Two more strips are attached to the back of the side bearings which is a 4” PVC closet flange extender that cost $2.68 each. The Velcro is black, industrial strength and used in the auto industry. Lowe’s and Home Depot sell a similar type that is two inches wide. Do not use the 3/4” white. It does not have the same strength as the two inch.

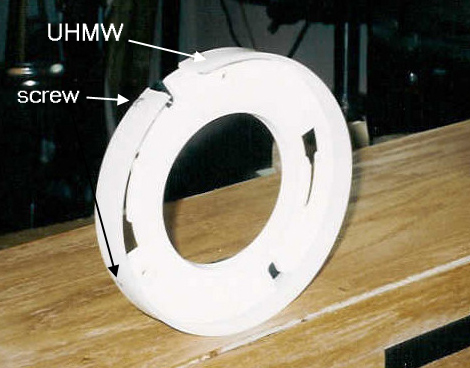

The closet flange extender is only 7/16” thick. To make it fit better with the 3/4” thick side board that it sits in. I wrapped some 1/8” thick by 1 inch wide Ultra High Molecular Weight Polythene (UHMW) around the closet flange. This increased the closet flange to 1” thick and the diameter to 7 1/4”.

This photo shows the UHMW screwed to the closet flange to make a complete side bearing. I have not found any readily available glue that will hold UHMW plastic to PVC and create a strong bond. There maybe some type of industrial glue available I just don’t where it is sold. The screws toward the bottom of the bearing are countersunk so they do not rub against the magic sliders.

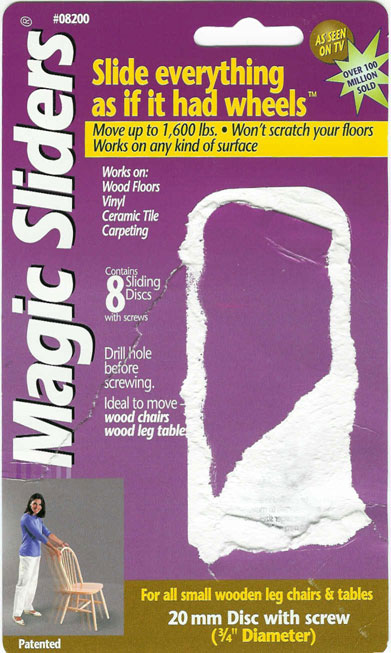

Do not confuse Magic Sliders with EZ GLIDE. The EZ GLIDE product is a dense fiber pad used as a floor protector on the bottom of chairs and tables legs. But in the ATM world they are used in large mirror cell flotation support systems, such as 9 to 27 point. They are used on the corners of the flotation triangles to support the primary mirror. I am not discussing large mirror cell systems; however, it is easy to confuse the two products.

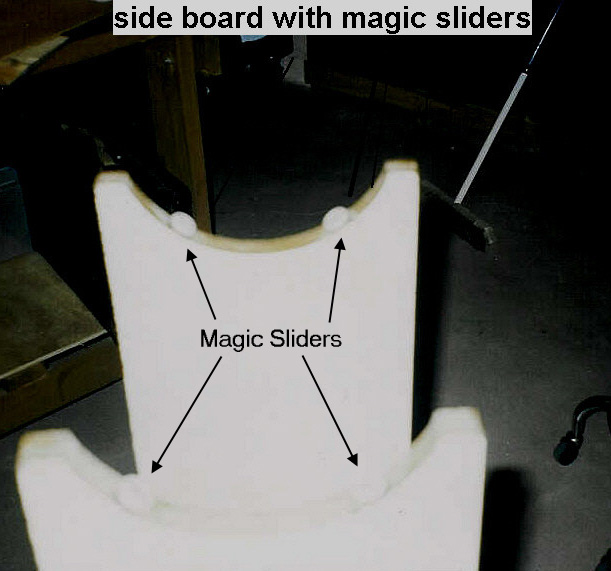

The telescopes side bearings ride on top of the magic sliders that are mounted on top of the cut out in the sideboard of the Dobsonian mount. The magic sliders have a hole in the center so you can screw them in place.

Spacing the sliders is another issue. Spacing the sliders farther apart increases the force needed to move the telescope. Moving the sliders closer together reduces the force needed to move the telescope. I have mine spaced about 90 degrees apart. The patented coated disks are gray and have a hard slippery surface.

I am sure some Lowbrows reading this have these on the bottom of chairs or table legs at home.

I have been to their website, www.Magicsliders.com and they do not discuss what the magic sliders are coated with or how they are manufactured. But I suspect it is some type of liquid Teflon based material. They come with their own screws and cost $6.98 for a package of eight, 20 mm disks. This combination of UHMW and magic sliders creates a very smooth feel that is comparable to the Teflon and ebony star Formica combination.

This combination has a very low coefficient of friction that requires very little force to overcome static frictional force.

In the October 2003 issue of Sky & Telescope magazine there is a very good article titled; Better Dobsonian Bearings, by Martin Lewis. It describes the different materials he tested, the test procedures he used and how the movement of the telescope is affected. One interesting technique was developing motion diagrams for the different combinations of materials he used. This article is a little tricky in understanding. But it is thought provoking.

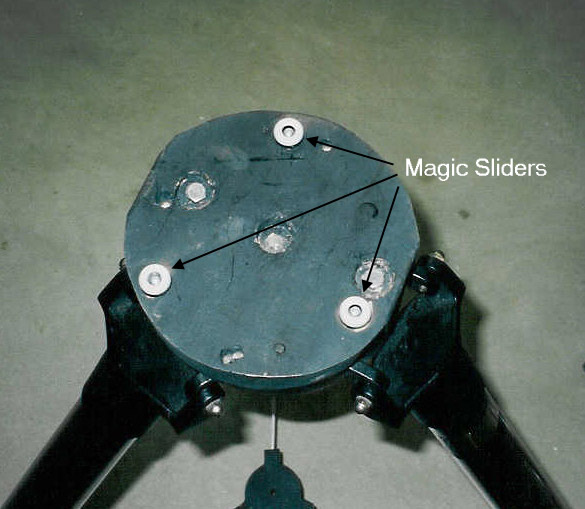

The picture below shows a Meade tripod mount. I cut out a round piece of wood and bolted it to the base of the tripod mount.

The magic sliders where spaced about 120 degrees apart and screwed into the wooden mount board. The ground board that is attached to the two sideboards was placed on top of the magic sliders and secured with a 3/8” bolt. A hole was drilled in the center of the ground board, so the bolt can pass through the ground board and screw into a 3/8” T-nut that is embedded in the wooden mount board on the tripod. This allows the Dobsonian mount to rotate on the magic sliders without any wobble.

The sideboards and the ground board are made from Thermo Fused Melamine shelf panels that have holes in them for shelf pins. Both sides have a hard laminate surface that has a fine-bubbled texture similar to ebony star Formica. These were left over parts sitting next to the ATM vault of stuff I forgot I had.

This makes for a very smooth azimuth bearing that requires little force to overcome static friction. The combination of Melamine panels and magic sliders can be used for larger telescopes. The magic sliders come in larger sizes as well as the Melamine panels.

I have read and talked to people that have waxed their ground board that sits on the Teflon pads for the azimuth bearing. I tried this on the bottom of my Melamine panel ground board that sits on the magic sliders, using Turtle Wax. I could feel that it took less force to overcome the static friction to move the mount. Depending on the size, weight and type of materials you use, this may or may not be significant in rotating the mount in the azimuth motion. You could probably use other types of silicon lubricants as well as dry lubricants.

There are many different ways to build a altitude/azimuth mount as well as materials available. It is called creativity and that is one of the neat things about Amateur Telescope Makers.

To any Lowbrows that are planning on building a Dobsonian mount, I still have about 50 feet of the 1/8” by 1” UHMW material left. If you are interested, I will give you enough to cover your side bearings. Years ago I sold this stuff at Astrofest and it works well. Of course the most important part about this offer is, I know where all the stuffs at.