on the Control Panel.

on the Control Panel.

Congratulations on completing the flowsheet and entering the process model conditions. Now you are ready to put your model to the test. Example 4-3, the cracking reaction, can now be simulated.

Once you've clicked OK to run the process model, the Control Panel window will appear. This window gives you a look at the ASPEN PLUSTM "thinking process." Phrases indicating the PFR block is being executed will scroll across the screen. When the simulation is complete, the Control Panel will read: Simulation calculations completed.

on the Control Panel.

on the Control Panel.

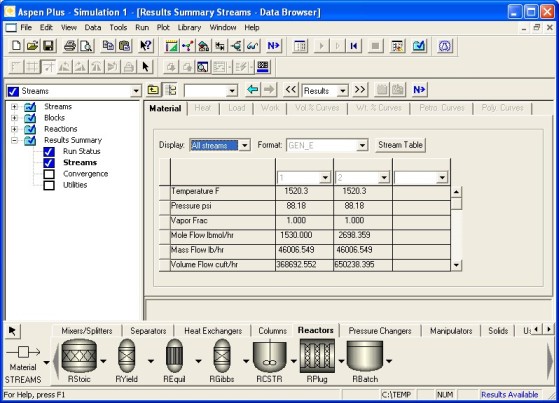

For the Example 4-3 simulation the stream results screen should look like this:

Note that, down the left side of the screen, are the different parameters: temperature, pressure, mole flow, etc. Along the top row are the stream id names, in this case 1 and 2 (inlet and product). This forms a grid of information that can be interpreted easily.

In Example 4-3, the problem asks for the PFR volume that will achieve an 80% conversion. As you recall, when entering the process model conditions, you guessed a volume by entering an arbitrary length and diameter of the PFR. In order to complete the problem, you must see what conversion your process model obtained. Recall that conversion is defined as:

Where moles reacted = moles in - moles out

To solve for conversion, do the following with the results:

If you followed the example exactly, using a length of 10 feet and a diameter of 3 feet, you should get a conversion of 76%.

X = 1530 lbmol/hr - 361.641 lbmol/hr

1530 lbmol/hr

X = 0.76 = 76%

The dimensions of the PFR did not achieve an 80% conversion. Therefore, you need to go back and adjust them. It is easiest to vary the length of the PFR while holding the diameter constant. In this example, since the conversion was too low, you must INCREASE the length of the PFR.

Changing Process Conditions and Rerunning the Model

Adjusting the input conditions is very straightforward, just follow these steps:

In Example 4-3, you will find that a length of 11.42 feet and a diameter of 3 feet will achieve an 80% conversion. To finish the problem, the volume of a PFR with these dimensions is V = 80.72 ft3.

Back to ASPEN PLUSTM Main Page