Customer: I'd like to know a bit about bookbinding, which I'm sure is crucial in this era because you really cannot have a book without the binding. Mr. Tonson, what are the steps in the bookbinding process?

Tonson: Well, the procedure goes something like this: Basically, the individual sheets of paper from the printer are beaten together with a hammer and pressed together tightly with plates and then sewn together to maintain order. Then, a press is used to hold the papers together, and the boards are attached. A cover is then placed over the boards. Lastly, finishing, trimmings, and decorations of the book are completed.

Customer: Do you know what the paper, boards, and covers are made of?

Tonson: Paper is made from linen or cotton throughout the eighteenth century, leading to a great deal of rag shortages.3 In terms of boards, rope-fibre millboard, unequaled for solidity, stability, and durability, is used for the bigger, more expensive books, while pasteboard is implemented incheap retail bindings.4 Covers are done with leather calf for the expensive books and sheepskin for the cheaper ones.5

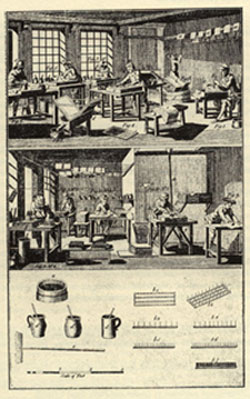

Pictured are two views of an eighteenth-century bookbindery and some of the tools of the trade.6

Customer: What kind of bookbinding innovations have come about in this century?

Tonson: There have been quite a few innovations in bookbinding in the eighteenth century. For example, recessed cord sewing was a big step forward from raised cord sewing. The use of millboard was a vast improvement over pasteboard; the books also have tighter backs at this time, making for a solid design, less heavy and crude. Books begin to have beveled edges at this time, which is a much cleaner and more attractive technique. Letters on the bindings of books have also been revolutionized with the growth of libraries. Many of these improvements have come about in the last quarter of the century when economic affluence has created many more aristocrats whose patronage offers brand new research and development options in bookbinding.7

Customer: I've heard that London's bookbinding is pretty exceptional compared to the rest of Europe. Is that true?

Tonson: It is true, and there are basically three main reasons why:

1. High Quality Materials: The English paper does not stick seeing as it is such high quality linen and cotton. The leather is thin and specially shaved, giving a lighter impression and improved strength and beauty. Finally, the boards are smooth and solid with nice sharp edges.

2. Division of Labor: The organization of the industry is excellent, as it is set up like a great factory where everyone learns all aspects of the process and then specializes. Master binders work on the fine bindings, and men deal with the heavier binding tasks, while women sew, fold, and pierce for less pay. The set up is perfect.

3. Tools are better: English have the best hammers, pallets, and fast cutting, strong presses.8Customer: England must have its share of bad bookbinders though too.

Tonson: The bad bookbinders take up space on Pasternoster Row and are bad due to the poor pay they offer, coupled with a complete lack of concern for quality. On a brighter note, the best bindings come from Westminsiter, where professional tailors actually take care of the binding.9

Customer: What is the relation between retailer and binder?

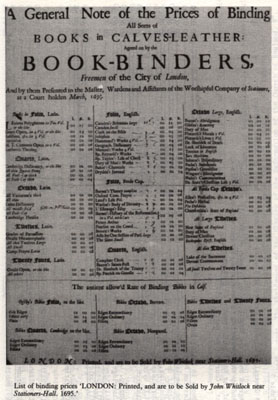

Tonson: Good question. There are set costs between the two parties.10 The retailer essentially sells both bound and unbound copies of books, with bound being more expensive. The binder also provides the retailer with cheap and fine types of bindings. A good relationship between the two is essential for business to function.

A binder's price list, which lists the prices levelled to the seller for an assortment of bindings.11

Customer: So where can I see some of these books?

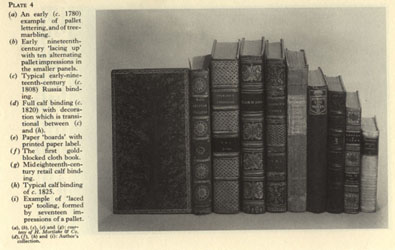

Tonson: There are a few lovely books below.

Back to Chat Printing Sales and Advertising Booksellers Literacy